Such information is critical to enable suitable bearings to be selected for both shafts. Mild steel needs more revolution at the worm gear input to fracture the specimen.

Agma Worm And Spur Gear Design Equations And Calculators

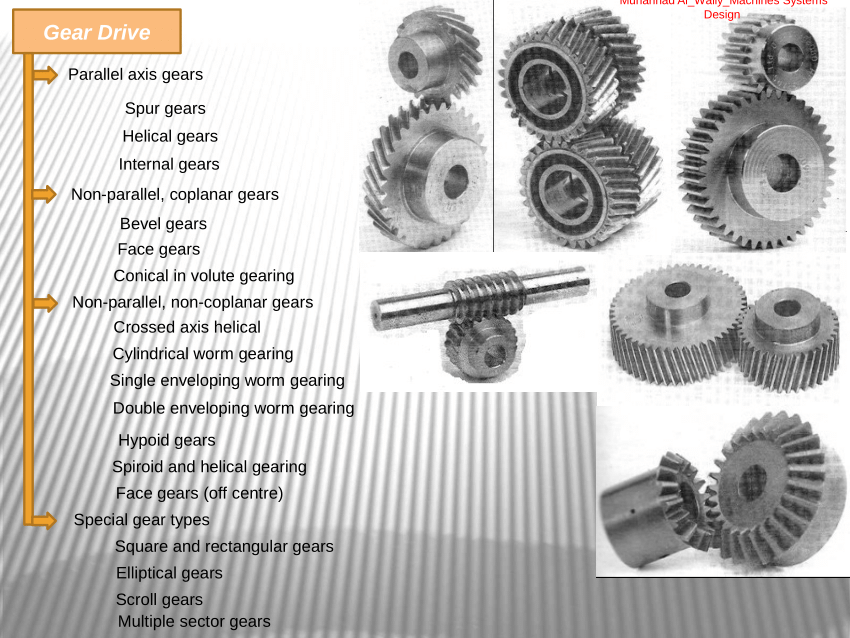

The procedure takes into account the pitting resistance surface fatigue failure and bending strength capacity volumetric fatigue failure of spur and helical gears.

. The AGMA power ratings based on wear and pitting resistance are presented in Section 113 and an associated design procedure in Section 114. Shigleys Mechanical Engineering Design 8th Edition. This is because cast iron is more brittle than mild steel it is loss ductile.

The gear box or the driving sprocket. The forw ard and revers e efficienci es for worm gearboxes are. A short summary of this paper.

Schematic concept of gear rolling device Figure 4. Some 2017-2021 Acadia XT5. Email protected email protected.

The gear system works together as demonstrated in the previous step. Welcome to the widest range of standard racks pinions in the World. Schematic concept of gear rolling.

Possible to point out a general procedure which will in the majority of cases prove to be helpful to the beginning designer. And 2020-2021 XT6 models equipped with the 20L engine RPO LSY LTG 25L engine RPO LCV or 36L engine RPO LFY LGX and All-Wheel Drive RPO F48 may have an illuminated Service AWD lamp on the instrument cluster and several Power Transfer Unit DTCs set C1260C1267. The white gear housing holds all the gear components together.

Worm and wheel gear-sets tend to fail due to pitting and wear see Dudley 1984. Full PDF Package Download Full PDF Package. Download full-text PDF Read full-text.

Shigley Mechanical Engineering Design 2015. A short summary of this paper. It is not an appropriate method to determine individual tooth flank errors.

Column 1 illustrates the procedure with photographs column 2 gives a brief key as well as tools to be used for each procedure and column 3 explains in detail the procedure you should follow. GK 2010 7 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 The SEW-EURODRIVE Group of Companies Introduction 1 Introduction GK 2010 11 The SEW. 6 Full PDFs related to this paper.

Before starting work on the design of. The purpose of this paper is to establish a procedure and formulas to estimate a value of gear expected life for a high number of cycles. The white worm gear from the green bullet below spins the circular gear which drives the arm up to resist R2s lever action.

Composite inspection is a useful shop-friendly tool to determine the general quality of a gear including size runout tooth-to-tooth rolling action and to detect nicks. Cast iron has high carbon content causing it to be very brittle and is weak in tension. This general procedure can be stated briefly in the form of several steps as follows.

0 Full PDFs related to this paper. Consisting of both helical straight spur tooth versions in an assortment of sizes materials and quality levels to meet almost any axis drive requirements. Full PDF Package Download Full PDF Package.

Pay special attention to the notes cautions and warnings.

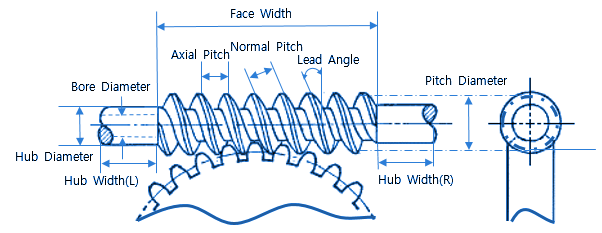

Worm Gearing Classes Proportions Materials And Worm Gear Cutting

Agma Worm And Spur Gear Design Equations And Calculators

Worm Gear Design Calculation Pdf Merge Peatix

Pdf Machine Design Ii Module 2 Gears Lecture 16 Worm Gears Worked Out Problems Contents Aju Joseph Academia Edu

Innovative Design For A Ball Worm Gear Mechanism Semantic Scholar

Worm Gear Design Calculation Pdf To Excel Mewhipware1979 S Ownd

0 comments

Post a Comment